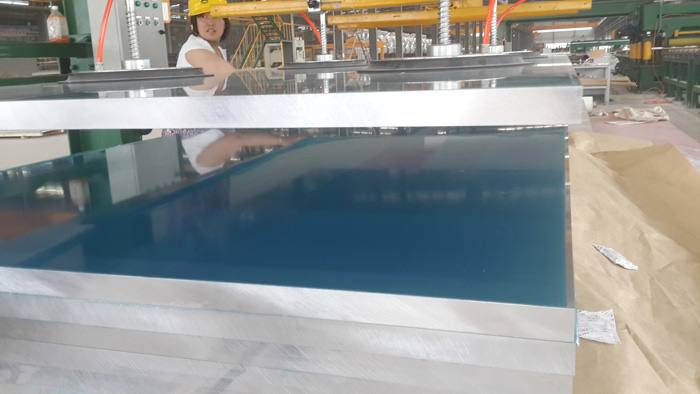

5083 aluminum sheet plate

Mega aluminum strict control of 5083 aluminum sheet products process, through the alloy composition, casting process optimization, homogenization heat treatment and rolling process test, the product performance and foreign materials, to meet user requirements, especially to satisfy the Marine aluminum plate, rail transportation, automotive, mold and other complex parts of the growing demand for the processing and application prospect is very broad.

Application of 5083 aluminum sheet

Rail cars

Shipbuilding

Vehicle bodies

Tip truck bodies

Pressure vessels

LNG storage tank

Mine skips and cages

GIS high voltage switch shell

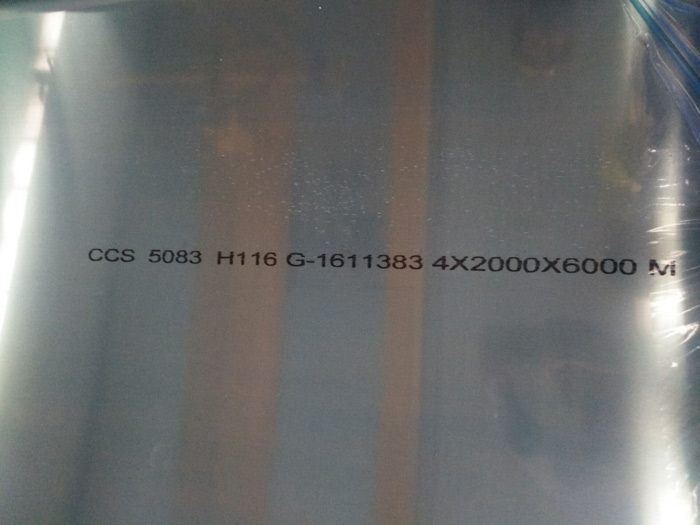

5083 aluminum sheet for ships: commonly used 5083H116/ h321/h112 status, Mega aluminum 5083 Marine grade aluminum plate has passed CCS China classification society certification and DNV Norwegian classification society certification, has been successfully used in yachts, cruise ships and other hull.

5083 aluminum sheet for vehicles: aluminum alloy tank car body/tank body, car oil tank, gas storage cylinder, bus skin, C82 coal transport vehicle, car roof/bottom protection plate, etc.

The main specification of 5083 aluminum sheet

| Alloy | Temper | Size | Standard |

| 5083 | H116 | 5*2000*8000 | CCS |

| 5083 | H116 | 12*2000*8000 | CCS |

| 5083 | H321 | 6*1219*2438 | LR |

| 5083 | H321 | 12*1219*2438 | LR |

| 5083 | H321 | 12*1500*6000 | ABS |

| 5083 | H321 | 16*1500*6000 | ABS |

| 5083 | H111 | 130*1500*3000 | GBT3880-2012 |

| 5083 | H321 | 5*2000*8000 | ASTM B928 |

| 5083 | H116 | 10*1830*6000 | DNV GL RULES (2017-07) |

| 5083 | H111 | 2*1500*3000 | EN485 EN515 EN573 |

| 5083 | O | 50*4000*13500 | JIS H4000 |

Features of our 5083 aluminum sheet

1. Corrosion Resistance

The typical application of 5083 aluminum sheet is in the marine environment. with more than 3½% mg Mg content, it can be susceptible to stress corrosion cracking, which limits its application temperature to below 65°C and also limits the amount of cold work to ¼ Hard.

2. Heat Treatment

The 5083 aluminum sheet can not be harden by heat treatment. It can be significantly hardened by cold work (cold rolling) and various “H”tempers are produced – most commonly H32 (¼ Hard) or the similar strength marine tempers H116 and H321 – as well as the soft annealed Temper O condition.

3. Welding

It can be Excellent weld-ability by all standard electric, GMAW and GTAW are preferred and widely used to produce structural welds.

Chemical Properties (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Others |

Aluminium min. |

|

| Each | Total | |||||||||||

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | - | 0.25 | 0.15 | 0.05 | 0.15 | Re. |

Specification of our 5083 aluminum sheet

1. Thickness: 0.15-600mm

2. Width: 500-2800mm

3. Length:500-16000mm

4. Temper:H16,H18,H19,H22,H24,H32,H111,H321,etc.

5. Certificate: DNV/ABS/Lioyds/BV

6. Feature: Corrosion resistance, high precision and fatigue resistance.

7. Tensile Strength:170~360MPa

8. Yield strength (MPa)≥65

9. Modulus of elasticity(E): 69.3~70.7Gpa

Mechanical Property

| Alloy | Temper | Thickness (mm) |

Tensile Strength Rm/Mpa |

Extension strength Rp0.2/Mpa |

Elongation (%) |

|

| No less | A50mm | A | ||||

|

5083 |

O H111 |

>0.20-0.50 |

275-350 |

125 |

11 | - |

| >0.50-1.50 | 12 | - | ||||

| >1.50-3.00 | 13 | - | ||||

| >3.00-6.30 | 15 | - | ||||

| >6.30-12.50 |

270-345 |

115 |

16 | - | ||

| >12.50-50.00 | - | 15 | ||||

| >50.00-80.00 | - | 14 | ||||

| >80.00-120.00 | 260 | 110 | - | 12 | ||

| >12.00-200.00 | 255 | 105 | - | 12 | ||

|

H12 |

>0.20-0.50 |

315-375 |

250 |

3 | - | |

| >0.50-1.50 | 4 | - | ||||

| >1.50-3.00 | 5 | - | ||||

| >3.00-6.00 | 6 | - | ||||

|

H22 H32 |

>0.20-0.50 |

305-380 |

215 |

5 | - | |

| >0.50-1.50 | 6 | - | ||||

| >1.50-3.00 | 7 | - | ||||

| >3.00-6.00 | 8 | - | ||||

|

H14 |

>0.20-0.50 |

340-400 |

280 |

2 | - | |

| >0.50-1.50 | 3 | - | ||||

| >1.50-3.00 | 3 | - | ||||

| >3.00-6.00 | 3 | - | ||||

|

H24 H34 |

>0.20-0.50 |

340-400 |

250 |

4 | - | |

| >0.50-1.50 | 5 | - | ||||

| >1.50-3.00 | 6 | - | ||||

| >3.00-6.00 | 7 | - | ||||

|

H16 |

>0.20-0.50 |

360-420 |

300 |

1 | - | |

| >0.50-1.50 | 2 | - | ||||

| >1.50-3.00 | 2 | - | ||||

| >3.00-4.00 | 2 | - | ||||

|

H26 H36 |

>0.20-0.50 |

360-420 |

280 |

2 | - | |

| >0.50-1.50 | 3 | - | ||||

| >1.50-3.00 | 3 | - | ||||

| >3.00-4.00 | 3 | - | ||||

|

H116 H321 |

>1.50-3.00 |

305 |

215 |

8 | - | |

| >3.00-6.30 | 10 | - | ||||

| >6.30-12.50 | 12 | - | ||||

| >12.50-40.00 | - | 10 | ||||

| >40.00-80.00 | 282 | 200 | - | 10 | ||

|

H112 |

>6.30-12.50 | 275 | 125 | 12 | ||

| >12.50-40.00 | 275 | 125 | - | 10 | ||

| >40.00-80.00 | 270 | 115 | - | 10 | ||

| >80.00-120.00 | 260 | 110 | - | 10 | ||

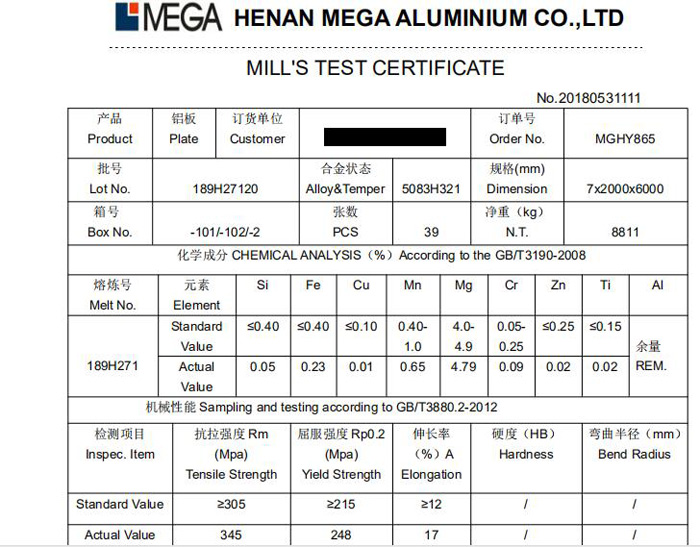

1. 5083H321, 7*2000*8000mm(with DNV certificate)

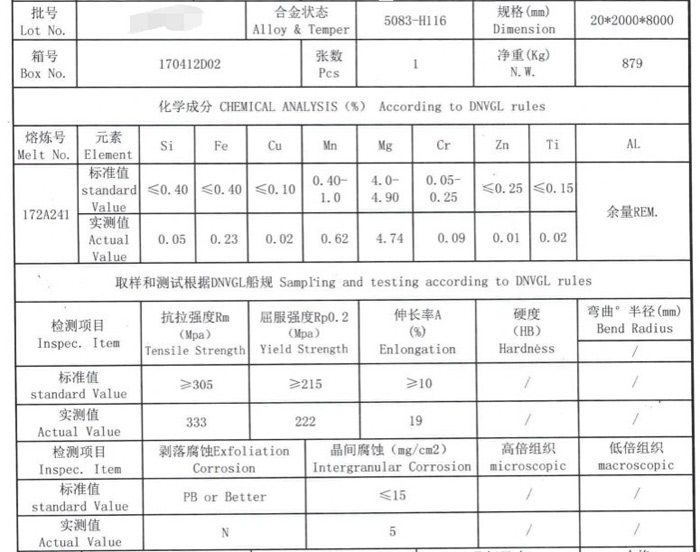

2. 5083H116, 20*2000*8000mm