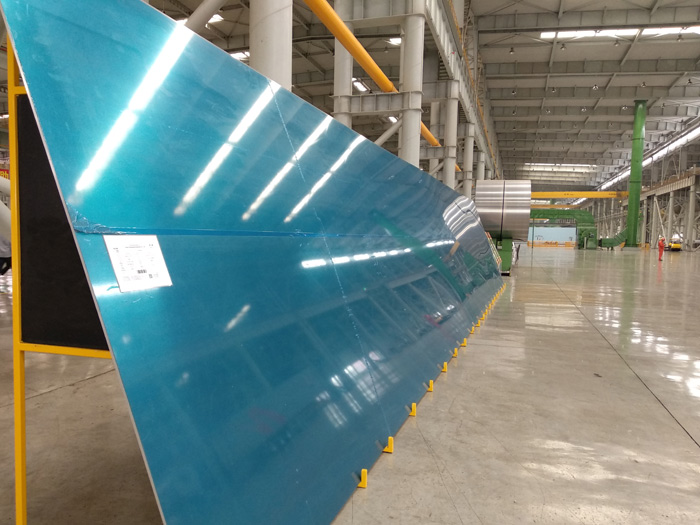

Aluminum sheet for LNG storage tank

LNG(Liquefied Natural Gas) storage tank is a professional product for storing liquefied natural gas, special equipment, three kinds of pressure vessels. It has been manufactured through flaw detection, hydraulic pressure and pneumatic test, on-site inspection by the technical supervision bureau, issuance of pressure vessel inspection certificate, external rust removal and painting and other processes.The LPG storage tank has strict quality identification on the material, appearance size, weld quality, operation quality, installation quality, internal devices and safety accessories of the pressurized components.

The main alloy which is used for LNG storage tank is 5083, 5182 and 5754.

Advantages of aluminum sheet in LNG storage tank

1. Excellent resistance in low-temperature environment

The on-board LNG storage tank belong to low temperature vessels, the design temperature is commonly - 196 ℃, the general material in the low temperature brittleness temperature next time, and aluminum alloy can be used to working condition of low temperature, low temperature resistance performance can reach to 269 ℃, even under the condition of low temperature, tensile strength and yield strength of aluminum sheet is harder, fracture toughness will be improved, the temperature of the on-board LNG storage tank design demand.

2. Low density

The existing on-board LNG storage tanks are mostly made of stainless steel, with high density. Due to material limitations, it has a relatively heavy dead weight, while the aluminum sheet is low density, which reduces energy consumption and saves costs in the use of on-board LNG storage tank.

3. Good corrosion resistance

The on-board LNG storage tank operation environment for the outdoor environment, more need of atmospheric environment with good corrosion resistance, aluminum sheet in use process, because of aluminum and oxygen in the air extremely easy oxidation reaction, make its surface to form a layer of dense oxide film, its strong adsorption ability, enough to make aluminum alloy has strong resistance to atmospheric corrosion.

The aluminum sheet for Tank top ceiling

Because aluminum sheet is lighter, it doesn't need that much force to float. Another reason is that aluminum sheet is not easy to rust on the quality of the medium has a certain guarantee.Floating roof is also because the flexible floating plate up and down can be close to the liquid level so as to greatly reduce the gas space above the liquid level, and thus can greatly reduce the evaporation loss of stored materials.

Our stock of LNG storage tank aluminum sheet (5083)

| Standard | Alloy | Temper | Size (mm) |

| ASTM B209 | 5083 | O | 7*2300*2700 |

| EN485 | 5083 | H111 | 6*2000*8000 |

| EN485 | 5083 | H111 | 6*2000*8000 |

| ASTM B928 | 5083 | H321 | 6*2000*8000 |

| ASTM B928 | 5083 | H116 | 6*2000*8000 |

| ASTM B928 | 5083 | H321 | 6*2000*8000 |

| ASTM B928 | 5083 | H116 | 6*2000*8000 |

| EN485 | 5083 | H111 | 6*2000*8000 |

| ASTM B928 | 5083 | H116 | 6*2000*8000 |

| ASTM B928 | 5083 | H116 | 6*2000*8000 |

| GB/T3880-2012 | 5083 | O | 7.94*2438.4*6039 |

| GB/T3880-2012 | 5083 | O | 7.94*2438.4*6039 |

| ASTM B928 | 5083 | H116 | 6*2000*8000 |

| ASTM B928 | 5083 | H116 | 6*2000*8000 |

| ASTM B928 | 5083 | H116 | 6*2000*8000 |

| GB/T3880-2012 | 5083 | O | 7.2*2400*2900 |

| GB/T3880-2012 | 5083 | H111 | 6*2000*2910 |

| GB/T3880-2012 | 5083 | H111 | 6*2000*2700 |

| ASTM B928 | 5083 | H116 | 6*2000*8000 |

| ASTM B928 | 5083 | H116 | 6*2000*8000 |

| ASTM B928 | 5083 | H116 | 6*2000*8000 |

| EN485 | 5083 | H111 | 6*2000*8000 |

| GB/T3880-2012 | 5083 | O | 7.94*2438.4*6039 |

| GB/T3880-2012 | 5083 | O | 7.94*2438.4*6039 |

| GB/T3880-2012 | 5083 | O | 7.94*2438.4*6039 |

| GB/T3880-2012 | 5083 | O | 7.94*2438.4*6039 |

| GB/T3880-2012 | 5083 | O | 7.94*2438.4*6039 |

| EN485 | 5083 | H111 | 6*2000*8000 |

| ASTM B928 | 5083 | H116 | 6*2000*8000 |

| ASTM B209 | 5083 | H321 | 6*2000*8000 |

| GB/T3880-2012 | 5083 | O | 7.2*2400*2900 |

| GB/T3880-2012 | 5083 | H111 | 6*2000*2700 |

| GB/T3880-2012 | 5083 | O | 7*2620*3000 |

| GB/T3880-2012 | 5083 | O | 7*2440*3000 |

| GB/T3880-2012 | 5083 | O | 7*2620*3000 |

| GB/T3880-2012 | 5083 | O | 7*2620*3000 |

| GB/T3880-2012 | 5083 | O | 6*2000*8000 |

| GB/T3880-2012 | 5083 | O | 6*2000*12000 |

| GB/T3880-2012 | 5083 | O | 6*2000*10000 |

| ASTM B209 | 5083 | O | 7*2300*2700 |

| ASTM B209 | 5083 | O | 7*2300*2700 |

| ASTM B209 | 5083 | O | 7*2300*2700 |

| EN485 | 5083 | H111 | 6*2000*8000 |

| GB/T3880-2012 | 5083 | O | 7.2*2400*2900 |

| GB/T3880-2012 | 5083 | O | 7.2*2400*2900 |

| GB/T3880/2012 | 5083 | H111 | 6*2000*2700 |

| GB/T3880-2012 | 5083 | O | 7.2*2100*2900 |