Aluminum plate for moulding

Moulding aluminum plate type refers to the use of aluminum alloy processing board material, moulding aluminum processing way belongs to the rolling processing, generally USES two ways: hot rolling and cast rolling, the main difference is whether can be anodized.

The difference use of hot rolling and cast rolling aluminum plate

Cast rolling moulding aluminum plate is used in the mold, and hot rolling moulding aluminum plate is suitable for stamping drawing. The physical properties of the same material vary greatly due to different manufacturing processes.

The feature of moulding aluminum plate

1. Customize is accepted

2. Surface polishing treatment

3. Accurate thickness tolerance

4. Anti-corrosion, good oxidation resistance and durability.

5. Good processing, no deformation after high speed machining.

6. Homogeneous material, unique grain refining process, no horizontal lines, bubbles, impurities.

Specification of moulding aluminum plate

| Alloy | Temper | Specification | ||

|

5052,5083, 5086 |

H111, H112,H116 | Thickness(mm) | Width(mm) | Length (mm) |

| 6-600 | 500-3500 | 1000-6000 | ||

| The special size can be customized | ||||

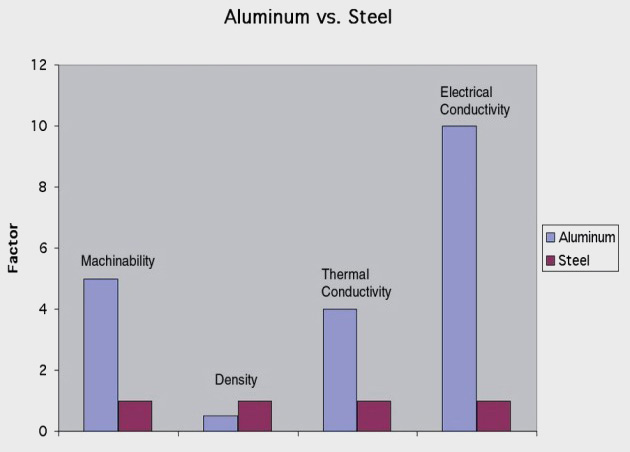

The moulding aluminum plate vs moulding steel

1. Light weight. Since its density is only 36% of the general mold steel, the inertia of the movement is relatively low. In the process of production, it is easy to reduce the speed and reduce the loss of the machine and mold.

2. Easy machining and high dimensional stability.The cutting speed is more than 6 times faster than that of the general die steel, so it can reduce the processing time of the mould so that the mold can be produced more quickly.

3. Excellent thermal conductivity.Its heat conductivity is higher than that of general mold steel, so it can save the cold cutting time of the mould at the production time by 50%, so as to improve the production efficiency of the mold.Therefore, it is widely used in 80% of products of different mold industries, such as injection mold, blow molding die, low pressure die and rubber mold.With the development of the market, currently in the European and American market ultra hard aluminum has replaced the steel mold.